In today’s time, creating an efficient product and delivering it is not easy, yet it is essential to survive in the market. Customers demand high-quality and efficient products to build trust. Even a single mistake can damage your company’s reputation. Smart machine vision sensors are continuously working to enhance quality. These sensors closely monitor all manufacturing processes and detect errors at every stage.

From reducing raw material wastage to increasing productivity, these solutions are driving the growth of industrial automation.

Table of Contents

Demand for smart machine vision sensors:

As per the Grand View Research study, the machine vision sensors are expected to be USD 20.38 billion in 2024. And it is expected to reach USD 41.74 billion by 2025 to 2030. It is growing at a CAGR of 13%.

What are the smart machine vision sensors?

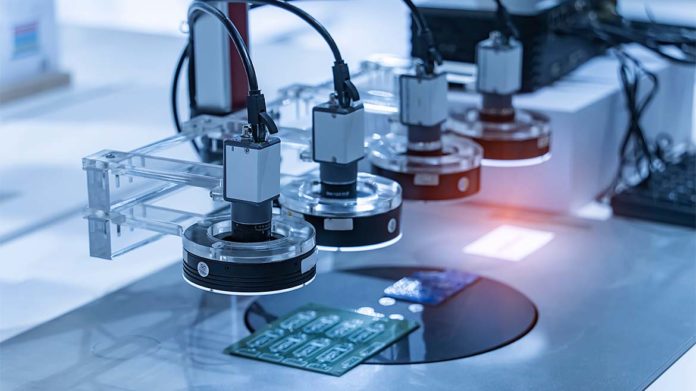

Smart vision sensors are specially designed imaging devices. They analyze and process data to improve inspections, monitoring, and measurement in industrial manufacturing. These sensors come with AI technology, which allows them to detect all errors and provide reports to the system. These sensors are installed in the production line to detect all errors or make quick decisions, identify scratches, misalignment, or measure colours. They can easily reduce wastage or errors in manufacturing and, automotive industries.

Key features of smart machine sensors:

- These industrial smart vision sensors provide high resolution image for all detects and errors.

- It detects all errors with AI-driven technology and takes immediate decisions.

- Smart machine sensors provide you the real-time data of your manufacturing unit.

- It integrates easily with various automation systems to enhance productivity and smart process management.

- It is suitable for all harsh environments because of its durable design.

- Reduce wastage in your manufacturing industry.

- Realtime monitoring of your productivity or reducing manual inspections.

Compact role of smart vision sensors in quality control

- Analyse defect: These smart vision sensors analyse and detect easily all errors in productivity, like cracks, dents, or any defect. Humans can also make mistakes in analyzing this, which a smart machine vision sensor cannot. It is capable of removing all errors immediately, or removing all errors and customer complaints.

- Measurement and inspection: a smart machine vision system completely measures all inspection and checks all components. It checks size, measurements, or dimensions and major problems. It strictly measures the quality standards and ensures that every part required specifications.

- Assembly verification: it measures all the parts of the assembled units, or ensures that no part is missing. It works with AI algorithms to verify pattern recognition. This prevents all those mistakes that can ultimately cause products to get damaged. And it helps in increasing productivity.

- Barcode and labeling verification: sensors scan the product’s barcode or label to track and record all products. These smart vision sensors automatically analyse or read these barcodes or labels, and remove wrong prints, colours, missing, and misplaced. This method is mostly used to keep proper and accurate records of manufacturing products.

- Consistent monitoring: these automation sensors continuously monitor all products and the productivity of size, shape, and quality. Sensors help to maintain quality standards or ensure the same quality for the customers.

What are the benefits of AI vision sensors in manufacturing?

- AI sensors help to enhance accuracy with the help of algorithms or reduce human inspection.

- Real-time monitoring sensors enhance the productivity of the industry by ensuring quality checks.

- These sensors reduce the wastage of raw material and reproduction.

- These sensors are reliable for various industries and can adapt different production lines or product types.

- It helps to maintain the manufacturing industry regulations and quality standards.

What are the applications of defect detection sensors?

These smart machine vision sensors are used widely across all industries. It helps to maintain quality control, production accuracy, or an industrial safety process. Sensors automatically detect product labels, colour, size, or motive to enhance overall efficiency or to satisfy their customers.

These sensors are implemented in various following industries.

- It detects paint jobs or assemblies in the automotive industry.

- This sensor is implemented in solder joints to inspect all errors in the electronics industry.

- Check packaging, labeling, Co2 in the food and beverage industry, to ensure labeling accuracy.

- In the pharmaceutical industry, it ensures the packaging, dosage, and safety seals of medicines.

- The textile industry analyzes colours and defects of the items.

These smart machine vision sensors also play a predictive maintenance system with the help of AI automation technology. Most of the manufacturers are adopting AI technology sensors to reduce unwanted defects in their manufacturing units or products.

Why Unseen Era is the best partner for improving quality control in manufacturing units?

Unseen era stands out as the best partner to detect or enhance productivity in your manufacturing units. Because we focus on enhancing the best customer satisfaction. Many companies trust Unseen Era, such as the pharmaceutical, food, beverage, and automotive industries. We deliver various insurance automation sensors, or high-tech gadgets, to our customers.

Major services by Unseen Era:

- GigE & USB Vision Camera

- Industrial camera lenses

- Industrial Vision Lights

- Industrial Smart Vision Sensors & Cameras

People Also Ask Smart Machine Vision Sensors: How They Improve Quality Control.

Q.1 What are the smart vision sensors?

A: These smart vision sensors are specially designed to analyse and detect errors. It measures or monitors products in real-time.

Q.2 Do these automation sensors use manpower?

A: No, these industrial automation sensors are specially designed to reduce manpower and detect human errors. These sensors perform better than humans and work faster.

Q.3 Do smart machine vision sensors support Industry 4.0?

A: Yes, this automation machine vision sensors fully support real-time data monitoring. Or it connects with automation and IoT platforms.

Q.4 Can smart machine vision sensors do predictive maintenance?

A: Yes, smart machines’ vision sensors do predictive maintenance by monitoring real-time data of the industry. It analyzes small defects or reduces downtime.