Engineered for Perfection — Unseen Era’s Orientation Check Systems.

In industrial manufacturing units, accuracy is not just about product quality or packaging, but it’s all about building customer trust. Even a small mistake can damage your company’s reputation and brand trust. That’s why the unseen era stands in the market because it delivers you unmatched speed, production, and consistency for running production lines smoothly.

Unseen era delivers you the unmatched orientation check sensors that are specially designed for the pharmaceuticals, manufacturing, and food preservatives industry. Our sensors help you to check, analyse defects, because they ensure flawless quality control and maximum productivity.

Various industries like pharmaceuticals, automotive, food and preservatives, and logistics industries trust the unseen era for orientation check systems.

What Exactly Is The Orientation Check System?

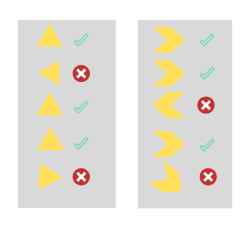

The orientation check system is an advanced industrial system that analyzes the defects and immediately verifies the correct & incorrect position of objects. Whether you are facing problems in ensuring the checking of bottle caps, label faces, and verifying all components in assembly lines.

Unseen era delivers you the smart verification system that enhances your system accuracy, productivity, and speeds up and more efficiently.

Why orientation matters in every industry?

In today’s fast-growing environment, the manufacturing & automotive industries are the most essential part of quality assurance. Because a minor error can damage the product and spoil the company’s goodwill.

- Wastage of raw material

- Reduce the time of wastage

- Increase the chances of customer satisfaction

- Analyse the defect labels

Our advanced high-tech technology helps you to eliminate the manufacturing defects & packaging errors to maintain the consistent quality and remove the manual inspection to maintain high speed & accuracy.

What are the key features of orientation check systems?

Unseen era, we deliver you the unmatched innovation, reliability, and consistent, precise engineering automation products that enhance efficiency, and are especially designed to check the product quality and measure defects.

- Ensure Maximum Productivity With High Speed: It detects all incorrect orientations that ensure the whole production runs correctly without interruptions. Our unseen era advances high-tech technology, accuracy, and fast production lines. Our main motive is to achieve the highest production targets, reduce downtime, and ensure consistent product quality.

- Multi-material quality check: Our unseen era orientation check system helps you to detect all errors in your production unit, with plastic, paper, and metal. This system is specially designed to handle all industrial applications with accuracy and efficiency.

- Smart Integration: All our automation sensors are easily connected to all of your machinery and production lines. Our products are designed to save time, cutting, and operational costs.

- Small design: Our orientation check system is dedicated to space saving because it fits easily in every industry.

- Durable material: The unseen era orientation check system is built for working in rusty, dirty, and high-temperature environments.

- AI-based technology: This system works with AI-based algorithms that analyse and learn the manufacturing and packaging process. This orientation check system helps to make quick decisions and reduce the error margin.

Why Choose An Unseen Era For The Smart Orientation Check System?

When it talks about industrial automation systems and AI-based sensor technology, Unseen Era stands out as the trusted partner in inspection solutions. We help various manufacturing industries to run their production smoothly, with high-speed detection, manufacturing errors, and ensuring the product quality. Whether you are operating manufacturing, automotive, or electronics industries, the unseen era delivers you the perfect solution for every industrial operation. Because we understand your precious time & costs.

Choosing an unseen era is the smart choice of every industrialist because our experience and smart orientation system redefine industrial efficiency.

What Are The Benefits Of Choosing Unseen Era Orientation Check System?

- Enhanced Product Quality: Our customized sensors are dedicated to ensuring your product quality, alignment, and accuracy.

- Guaranteed Increased Productivity: orientation check system easily integrates with your every industrial mechanism and analyzes, detects all defects with high speed accuracy, and ensures you reach our production levels to new heights.

- Error-Free Automation: unseen era automation solution detects every minor error from your production lines and immediately tells you all packaging issues.

- Cost Efficiency: Our sensors are built with smart automation techniques and a robust design that works with AI-based technology. It reduces the wastage of raw material, labor costs, and inspections.

- Brand Reliability: we helps every industry to build market trust, customer reputation, and customer loyalty.

People Also Ask About The Orientation Check System.

Q.1 Does the unseen era orientation check system align with my automotive industry?

A: Yes, the unseen era orientation check system easily integrates with your automotive industry because it ensures the alignment and product quality instantly. This automotive sensor works with accuracy and product efficiency.

Q.2 What types of products does your orientation check system detect?

A: unseen era orientation system working with a wider range of bottle caps, packaging labels, and all parts of metal, glass, and paper.

Q.3 Does Unseen Era deliver installation service for the orientation system?

A: Absolutely, unseen era delivers the installation services for all industries like manufacturing, pharma, and the automotive industry.