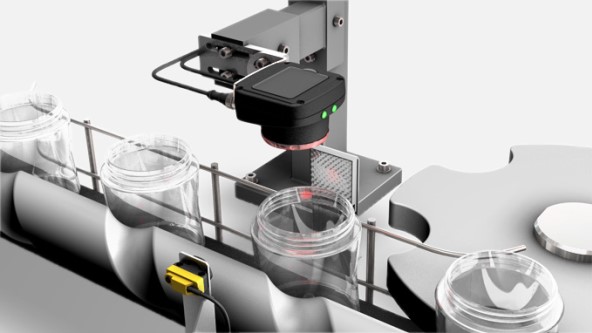

In the evolution of the industrial environment, speed, quality, and efficiency play a crucial role in business and workers’ safety. Customers expect flawless production of products, and manufacturers cannot afford machine downtime, production, or costly repairs. At Unseen Era, we deliver the VU Smart Vision Sensor, which is a smart and effective solution to make industrial inspections. This device is one solution for all problems to evaluate your business automation and production process.

It comes with a camera, lens, touchscreen, and lights that detect defects. The AI vision sensor ensures consistency to maintain world-class quality standards. Our iVU Smart Vision Sensor helps manufacturers across the inspection and automation process.

Introducing the iVU Smart Vision Sensor By Unseen Era

Our IVU smart machine vision sensor combines the quality of a photoelectric sensor with the intelligence of a smart machine vision system. These automation sensors help to inspect the products at the next level by evaluating the type, shape, size, and condition of the product.

Major key features:

- This sensor has an all-in-one design camera lens, lighting, or a single compact device.

- Touchscreen is easy to monitor all data, and without needing additional software.

- The main feature is that it is built with IP67 industrial housing to make it dust-proof, water-resistant, and suitable for harsh conditions.

- It works with multifunctionality because it inspects product quality, types, presence, and the position of products.

- Fast, accurate outcomes with the touchscreen interface.

Smart Applications of the iVU Vision Sensor

The iVU vision sensors are mostly used in multiple industries and applications to improve reliability, reduce errors, and automate inspections.

| Industry | Applications | Benefits |

| Manufacturing industry |

|

|

| Pharmaceuticals industry | It verifies the packaging, labeling, and ensures the expiry dates of medicines and storage. |

|

| Food and beverage | The smart sensor ensures proper packaging and labeling, preventing contamination. |

|

| Automotive industry | Inspect every minor bolt, paint, and ensure the assembly of production lines |

|

Benefits of Using Industrial Smart Vision Sensors in Business

The iVU smart vision sensor gives you various benefits when you use it in a production unit.

- Excellent quality control: This advanced automated sensor protects brand reputation. By identifying defects early, it ensures only high-quality products reach your customers.. This sensor helps to reduce recalls and claims or increase customer satisfaction.

- Increase productivity: The automated sensors eliminate manual inspections because faster than manual labor. Manual checks reduce downtime and ensure your production line runs at full capacity.

- Cost saving: These automated sensors minimize rework, manual labour, and scrap. Because these automated sensors quickly pay for themselves.

- Consistent working: This sensor is not like human inspectors. Vision sensors are not tired and give valuable results with accuracy and reliability.

- Easy to install: This is an all-in-one device that gives you multiple components’ benefits safely. You do not need to purchase any separate sensors to monitor and track the accuracy of the business.

- Future forecasting technology: the industrial networks are designed to be integrated with manufacturing units to monitor and support industrial 4.0 technology.

Why Unseen Era is the Best Partner For the Manufacturing Vision Sensor?

Unseen Era stands as one of the top industrial smart automation solutions. We deliver several years of experience, more than a decade. Our world-class iVU smart vision sensor offers various industrial vision systems like automated sensors, industrial barcode scanners, and readers for manufacturing units. Many industries trust Unseen Era for our reliable industrial automation services.

Where we deliver:

- Pharmaceutical industry

- Manufacturing units

- Food and beverage industry

- Automobile and electronics industry

Key features of choosing our sensors

- Complete guidance with sensor lenses and lights.

- Compact IP67 robust design for the plant

- Touch screen for examination and inspections

- Detect errors without delay

- After-sales support

Connect with us:

If you want to know more about the iVU smart vision sensor, feel free to connect with our team.

Email Add – uae@unseenera.com

Location – Dubai, United Arab Emirates (UAE)

Mobile No – +971-52-2697872

Frequently Asked Questions About the iVU Smart Vision Sensor

Q.1 How does a smart vision sensor work in manufacturing units?

A: The smart machine vision sensors examine all production lines to detect every minor erosion. It scans barcodes, sizes, and monitors real-time data in the industry. It works with AI-based detection algorithms to ensure faster inspection accuracy and reduce errors in production lines.

Q.2 Do iUV smart vision sensors increase productivity in industries?

A: Our smart vision sensor detects every defect and reduces manual inspection and human errors. This automation sensor increases the speed of production lines and ensures the quality, increasing overall productivity.

Q.3 How to install smart vision sensors in traditional product lines?

A: Our smart sensors come with mounting and key inspection points to connect with traditional product lines easily and a power network.

Q.4 How does this smart sensor reduce production cost?

A: Yes, our smart machine vision sensor reduces production cost by eliminating defects, reducing scrap rework, and eliminating manual inspections of labor inspections. This process saves time and leverages AI algorithms to minimize production errors.