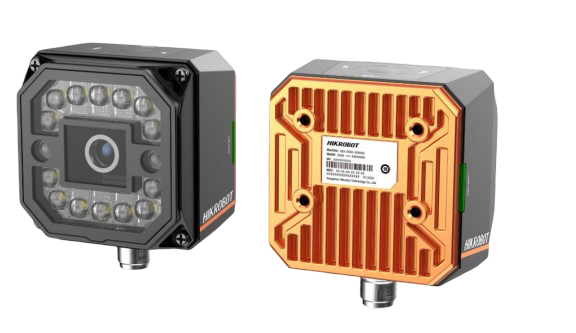

Grow your automation and quality control process with the 1.6 MP Vision Sensor, built for industries where accuracy, speed, and reliability are non-negotiable. Designed for production environment, this sensor from Unseen Era combines high resolution imaging, advanced processing capabilities, and strong industrial design to deliver unmatched performance in inspection, guidance, and verification applications.

Key Specifications of 1.6MP Vision Sensor

Unmatched Image Clarity and Precision

At the core of the sensor lies a 1.6 megapixel CMOS image sensor, delivering crisp, high definition images that captures fine details with precision. Whether identifying small defects, checking assembly alignment, or reading complex barcodes, the 1.6 MP sensor makes sure every inspection is accurate. Its high-resolution imaging allows for precise measurements, allowing manufacturers to maintain strict quality standards and reduce expensive errors.

Real Time Processing for Maximum Efficiency

Speed is crucial in modern production lines, and the 1.6 MP vision sensor is excellent in delivering rapid, reliable results. Having advanced onboard image processing algorithms, the sensor can handle high-speed inspection tasks without reliance or external processing units. Its high frame rate makes sure that every product passing through the line is captured, analyzed, and validated in real-time, reducing downtime.

Flexible Integration for Industrial Systems

Seamless integration into your existing automation setup is a priority. The 1.6 MP Vision Sensor supports major industrial communication protocols, including Ethernet/IP, Modbus TCP, and Profinet, allowing it to connect effortlessly with PLCs, HMIs, robotic arms, and other automation systems. Its intuitive configuration software simplifies setup and calibration, enabling quick deployment and minimal training for operators.

Durable, Industrial-Grade Design

Industrial environments are challenging, with vibration, dust, and temperature fluctuations that can compromise equipment. This vision sensor is engineered for rugged performance, featuring a robust housing and industrial-grade components that withstand harsh operating conditions. From the factory floor to automated assembly lines, the sensor provides consistent, reliable operation over the long term.

Versatile Applications Across Industries

The versatility of the 1.6 MP Vision Sensor makes it an ideal choice for a wide range of industrial applications:

- Automated Inspection: Detect defects, scratches, or inconsistencies on manufactured parts.

- Assembly Verification: Ensure components are properly aligned and installed.

- Robotics Guidance: Enable robots to identify, pick, and place parts accurately.

- Barcode and Label Reading: Quickly capture codes in high-speed production lines.

- Pharmaceutical and Food Processing: Maintain quality standards and regulatory compliance.

No matter the industry, this sensor helps companies streamline operations, reduce waste, and enhance product quality.

Advanced Features for Enhanced Performance

- 1.6 MP CMOS Sensor: Captures detailed images for precise inspection.

- High Frame Rate: Supports high-speed operations without missing a product.

- Integrated Lighting Options: Adjustable lighting ensures consistent imaging in various conditions.

- Rugged Industrial Housing: Resistant to dust, vibration, and extreme temperatures.

- Easy Software Configuration: Simplified setup, calibration, and monitoring.

- Multiple Communication Protocols: Ethernet/IP, Modbus TCP, and Profinet for seamless integration.

Why Choose the 1.6 MP Vision Sensor?

In competitive manufacturing environments, even the smallest error can impact productivity and profitability. The 1.6 MP Vision Sensor addresses these challenges by providing reliable, high-resolution imaging and real-time inspection capabilities, all while integrating seamlessly into existing automation systems. Its durable construction ensures long-term performance, while advanced algorithms and versatile connectivity deliver accuracy, efficiency, and scalability.

With this sensor, manufacturers can:

- Reduce operational errors and improve quality assurance

- Increase production speed without compromising accuracy

- Integrate easily into modern automation systems

- Achieve consistent inspection results across multiple production lines