In today’s rapidly developing technology world, every industry requires faster, more accurate, or higher-quality solutions. Every single or minor step counts in the industrial sector; that’s why Unseen Era offers you the quality vision measurement system that specializes in measuring every difference.

If you are an automotive industry owner or in electronics, you understand the need to maintain consistent quality and the challenges in high-speed production. When you use a manual inspection system it slows down your production, measurement solution, or introduces human errors. That’s why the smart industrial owners are switching to AI-based measurement solutions that are powered by a smart vision system.

Why Do Accurate Measurements Matter In Industries?

Imagine if you have a large-scale business that manufactures thousands of product pieces every hour, when suddenly a one component is off by a minor mistake or mislead. So it also affects the measurement, safety, and alignment of the production. Because measurement is the backbone of every industry, it ensures every product matches customer choices or is exactly uniform.

Unseen era automated measurement system matched with your precision and quality process, which enhances your industrial speed, readability, or reduces human errors.

What Makes It Different From Other Measurement Systems In The Unseen Era?

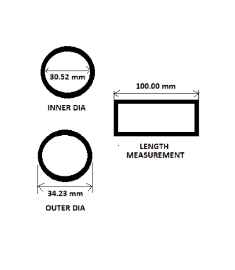

Our vision measurement system is specially focused on your industry designs to deliver you a faster, accurate, and fully measured system across large industrial applications. This vision measurement system is specially designed for industrial environments that integrate with your performance production lines, and provides you with real-time data analytics to make quicker, smarter, faster, or accurate decisions.

- This measurement system comes with ultra-high accuracy with a resolution as low as 10 microns. Weather talk about micro gear electronic systems, modern plastic parts, or real-time data analytics to make you smarter.

- Unseen era measurement system easily inspects 500 parts per minute, making it a perfect fit for large-scale production.

- Automated quality assurance tests your 100% products; it is not based on measuring only samples.’

- Data management is cloud-based premises that support your connectivity or offline servers. It ensures your data is secured, easy to track, and accessible.

- It combines with 21 CFR Compliant Software that easily meets regulatory requirements in pharma, food, or manufacturing industries.

- All the inspection images are stored securely to provide you with a digital audit trail for verification, traceability, and long-term data analytics.

What Are The Applications Of An Industrial Measurement System?

The unseen era industrial measurement system is easily adaptable for production environments. Whether you own a manufacturing, food & beverage, or pharmaceutical industry. Because quality testing is essential in all industries.

Applications include:

- Electronics component measurement

- Food measurement

- Metal & plastic measurement

- Medical packaging measurement

- General manufacturing measurements

Features Of The Unseen Era Automated Inspection System

- 500 products are inspected in one minute

- Easily integrate with cloud & offline servers

- Comes with 21 CFR Software

- Image storage available

People Also Ask About The Unseen Era Precision Measurement System

Q.1 Does this measurement system reduce material wastage?

A: The unseen era product measurement system easily reduces material wastage because it ensures precise measurement and reduces production errors.

Q.2 How much storage capacity does the measurement system have for image inspection?

A: The industrial measurement system comes with a higher storage capacity and stores thousands of images for inspection or data analytics.

Q.3 Does the measurement system work without internet connectivity?

A: Yes, the precision measurement system works with the internet or without the internet.