The UAE’s manufacturing sector is undergoing a digital revolution. Driven by the government’s Operation 300bn strategy, the goal is clear — to make the UAE a global industrial powerhouse. As competition and expectations rise, manufacturers are looking toward intelligent technologies to elevate productivity, reduce errors, and enhance quality.

One of the most transformative advancements in this journey is the adoption of industrial vision systems. These high-tech solutions are helping factories automate inspection, improve quality control, and achieve consistent production outcomes. Companies like Unseen Era are playing a vital role in making these systems accessible, customizable, and effective for UAE manufacturers.

Table of Contents

What Are Industrial Vision Systems?

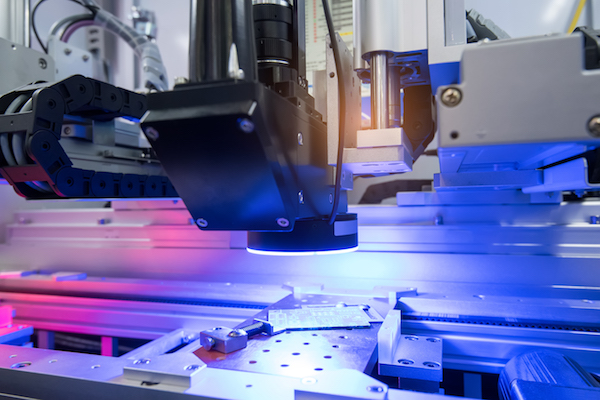

Industrial vision systems use advanced imaging hardware and intelligent software to replicate human vision — but with much higher accuracy, speed, and consistency. These systems consist of high-resolution cameras, specialized lighting, image sensors, and software algorithms.

They are primarily used to:

- Detect surface and structural defects

- Measure components with precision

- Verify assembly and part alignment

- Read barcodes and QR codes

- Classify or sort items based on shape, size, or color

Types of vision systems include:

- 2D vision systems for flat surface inspection

- 3D vision systems for depth and volume analysis

- Smart cameras with built-in processing capabilities

Why Industrial Vision Systems Matter in Modern Manufacturing

In high-volume production, even a minor defect or misalignment can lead to significant losses. Industrial vision systems eliminate guesswork and enable:

- High-speed quality inspection without disrupting workflows

- Improved accuracy beyond human capability

- 24/7 monitoring with real-time alerts and defect logs

- Data-driven decisions, helping improve design and processes

This level of precision and control is essential for manufacturers looking to meet international standards while reducing downtime and waste.

The UAE’s Manufacturing Landscape – A Sector in Transformation

The UAE’s manufacturing sector is rapidly modernizing. From food and beverage to electronics and pharmaceuticals, industries are embracing Industry 4.0 solutions like IoT, robotics, and AI to stay globally competitive.

Key drivers include:

- Government initiatives such as Operation 300bn

- Focus on localization and in-country value (ICV)

- Increased export goals requiring high quality standards

Industrial vision systems are now a cornerstone of this transformation, providing UAE factories with the intelligence they need to meet global benchmarks.

Key Applications of Vision Systems in UAE Manufacturing

Here’s how vision systems are being used across various manufacturing sectors:

1. Quality Inspection

- Detect scratches, blemishes, dents, or foreign particles

- Check for packaging or labeling errors

- Ensure uniformity in size, color, and shape

2. Assembly Verification

- Confirm presence/absence of parts

- Detect incorrect assembly or orientation

3. Measurement and Alignment

- Micron-level measurements for electronic or mechanical parts

- Validate tolerance ranges automatically

4. Sorting & Classification

- Separate products based on type, grade, or defect level

- Improve line efficiency and reduce manual sorting

5. Code & Label Reading

- Barcode and QR code reading for traceability

- Ensure compliance with shipping and safety standards

How Unseen Era Is Leading the Change

At the forefront of this transformation is Unseen Era, a UAE-based company specializing in industrial automation sensors and smart solutions.

What Unseen Era Offers:

- Advanced color, label gap, photoelectric, and ultrasonic sensors

- Integrated industrial vision systems tailored for each manufacturing line

- Expert consultation and installation support

- Scalable solutions adaptable to small, medium, or large enterprises

With a commitment to innovation and quality, Unseen Era helps manufacturers integrate vision technology seamlessly into their production environments.

Benefits Manufacturers Are Seeing with Unseen Era Solutions

By adopting Unseen Era’s vision systems, manufacturers are realizing measurable improvements:

- Higher productivity: Continuous inspection without manual intervention

- Lower defect rates: Immediate defect detection leads to less rework

- Better quality control: Uniform product standards are maintained across batches

- Regulatory compliance: Automated tracking and documentation simplify audits

Unseen Era also provides localized technical support, ensuring smooth deployment and ongoing performance monitoring.

Future Trends: Vision Systems & Smart Manufacturing in UAE

The future of manufacturing in the UAE is intelligent and automated. Industrial vision systems are evolving with new technologies like:

- AI and Deep Learning: Enhanced defect detection with self-learning algorithms

- Edge Computing: Faster processing at the machine level

- IoT Integration: Real-time updates on machine health and product quality

- Cobots (Collaborative Robots): Vision-enabled robots working safely alongside humans

Why Choose Unseen Era for Industrial Vision Integration

Unseen Era stands out in the UAE market for its:

- Domain expertise in factory automation and sensor technology

- Local presence, offering faster support and consultations

- Custom-built solutions tailored to each industry’s needs

- Reliability and after-sales service that ensures peace of mind

- When you work with Unseen Era, you get more than just equipment — you get a technology partner.

FAQs About Industrial Vision Systems in Manufacturing

Q1: Can vision systems replace human inspectors completely?

A: While vision systems are faster and more consistent, human inspectors may still be needed for final validation or tasks requiring subjective judgment. However, the need for manual inspection is significantly reduced.

Q2: Are these systems suitable for small manufacturers?

A: Yes. Unseen Era provides scalable solutions, making it possible for even small and medium enterprises (SMEs) to benefit from industrial vision systems.

Q3: How long does it take to implement a vision system?

A: Implementation time varies based on complexity, but generally takes 1–3 weeks, including installation and calibration.

Q4: What kind of maintenance is required?

A: Regular cleaning of lenses, software updates, and occasional calibration are typically sufficient. Unseen Era offers maintenance support for hassle-free performance.